Grandar, innovation company of designing and manufacturing custom acrylic display products rooted in advertising industry for over 20 years.

Since then, we have kept providing professional OEM/ODM services for our customers who come from different industries.

Looking forward to the future,

Grandar is going to serve more brands like we always do.

About Acrylic Production Process

Laser / Drilling / CNC

With our best technology(Laser / Drilling / Edge Beveling / CNC) and high-end machines, we will make the best acrylic product for you.

UV Printing / Silk Screen Printing

Bright & colorful images can be achieved with our top of the line UV printer. You can print your logo, label, or name of your business in full color on any piece of acrylic and proudly advertise to your audience.

Hot bending / Brushing/Polishing

A variety of acrylic processing techniques can be freely selected and combined to make artistic creations and meet your diversified requirements for different product promotion purposes.

Gluing

A variety of special glues for acrylic are bonded and fixed, and achieve perfect bubble-free bonding with our professional experience.

Packing

We provide a variety of packaging supplies to meet customers’ needs, and also encourage and support the local manufacturers in Foshan to coordinate to supply products that customers need.

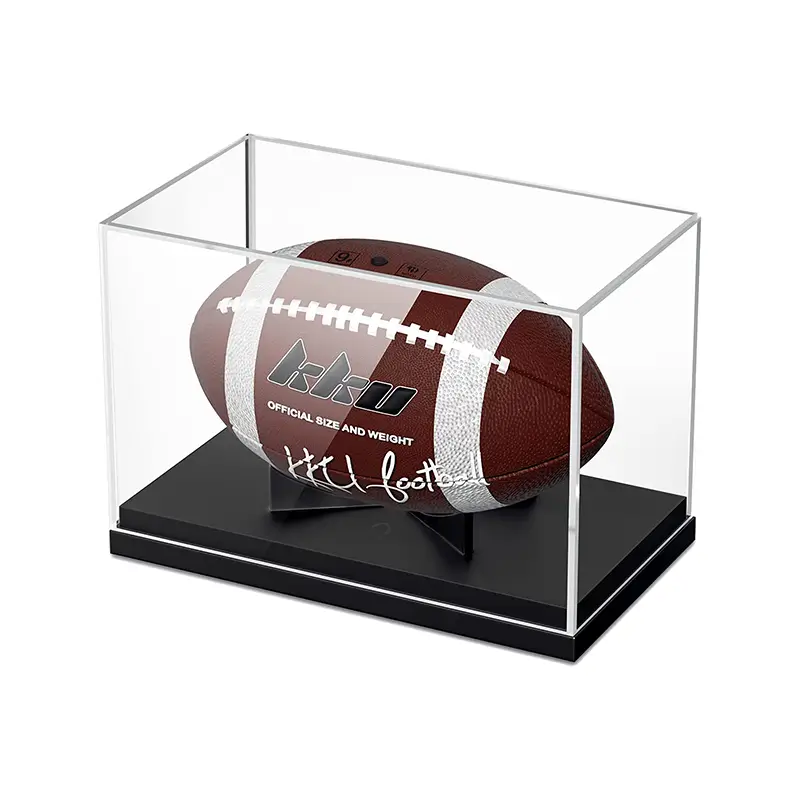

We Supply Various Custom Acrylic Products

COMMON DISPLAY PRODUCTS

Acrylic Case, Collection Box, Stationery Organizer, Display Shelf & Frame,Jewelry Stand, Acrylic Stair and Riser, Coin Holder, Display Rack, etc.

DESIGN STUDIO

GRANDAR.

BRANDING

GRAPHIC

INDUSTRIAL

PACKAGING

If you wanna get a creative design to start or enhance your business, feel free to contact us and we provide full custom acrylic support, from ideation and design to manufacturing and delivery.

Whether you need eye-catching displays, innovative signage, engaging promotional items, or any other acrylic product, our experienced design team is here to turn your ideasinto reality.

Grandar's Factory

OVER 10,000 SATISFIED PROJECTS IMPLEMENTED IN HERE

2000 square meterself-owned factory

Standardizedproduction line

ProfessionalSkilled Workers

High level ofmechanization

Acrylic Production Technology

Our manufacturing processes combine precision, efficiency, and innovation to meet the diverse needs of our customers. From sheet extrusion and casting to thermoforming and fabrication, we employ industry-leading techniques that ensure the highest quality standards in acrylic production.

Superior Acrylic Material

We believe that the quality of the raw material plays a vital role in the end product. Our acrylic sheets are carefully selected to guarantee excellent optical properties, UV resistance, impact strength, and chemical resistance. With our superior acrylic materials, we can create products that are not only visually stunning but also built to withstand the test of time.

Efficiency and Productivity

Our advanced machinery, combined with rigorous quality control measures, ensures consistent results throughout the production process. From material handling to shaping, finishing, and assembly, our equipment contributes to maintaining the highest standards of quality in every acrylic product we manufacture.